- NEWS

- the EDIT

- COMMENTARY

- BUSINESS

- LIFE

- SHOW

- ACTION

- GLOBAL GOALS

- SNAPS

- DYARYO TIRADA

- MORE

Dyson's latest purifier is equipped with upgraded filtration, delivers double the airflow compared to previous Dyson purifiers and sets a new standard in acoustics, taking indoor purification further — literally.

Dyson’s quietest yet most powerful purifier, the Dyson Purifier Big+Quiet Formaldehyde, is borne of Dyson’s longstanding expertise in airflow, acoustics, filtration, and compressors. Its new Cone Aerodynamics airflow delivery system offers more than double the airflow of previous models, reaching up to 87 litres per second of purified air up to 10 meters, with a new CO2 sensor indicating when to ventilate.

The re-engineered motor bucket ensures quiet operation through meticulous acoustic solutions, including a Helmholtz silencer and labyrinth seal. Its improved three-phase filtration system captures up to 99.95 percent of haze particles, removes three times more NO2 compared to previous Dyson carbon filters, and permanently destroys formaldehyde, with a five-year HEPA filter life.

Dyson shares its latest air purification technology, designed for large spaces. The Dyson Purifier Big+Quiet Formaldehyde uses Cone Aerodynamics to deliver 10-metre projection, a new K-Carbon filter for 3x better NO2 capture and introduces a CO2 sensor. Alongside powerful projection, the Dyson Purifier Big+Quiet Formaldehyde is also engineered to operate quietly, producing just 56 decibels of noise — making it Dyson’s quietest yet most powerful purifier.

“The Dyson Purifier Big+Quiet Formaldehyde marks the introduction of the Dyson large-format purifier – specifically engineered to purify quietly, efficiently and most importantly, thoroughly, in large rooms. Powerful projection of up to 10 meters ensures clean air is projected to every corner, whilst operating quietly even at full power – so you can say goodbye to the disruption of noisy purifiers and the inefficiency of weak airflow projection,” said Matt Jennings, Dyson's engineering director for environmental care.

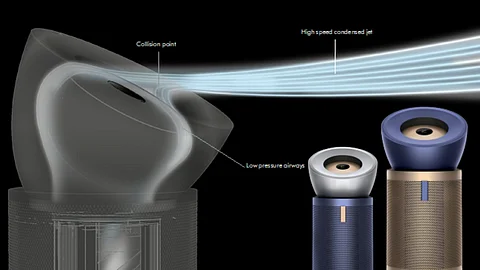

The Dyson Purifier Big+Quiet Formaldehyde represents a step-change in air purification, as Dyson engineers address the problems with weak airflow projection in large rooms. Conventional large-format purifiers typically diffuse air upwards. To achieve better, they developed a new energy-efficient, low-pressure air delivery system: Cone Aerodynamics.

Cone Aerodynamics uses the Coanda effect to merge two streams of air over a smooth surface, resulting in a powerful and condensed jet of air that can be projected of up to 10 meters, with minimal noise. It delivers more than double the airflow of the previous generation Dyson Purifiers. Powerful projection is critical to ensure that the machine effectively delivers clean air to every corner and displaces dirty air back towards the filter. The Dyson Purifier Big+Quiet Formaldehyde projects purified air at angles of 0o, 25 o or 50 o depending on user preference.

As with all Dyson purifiers, the Dyson Purifier Big+Quiet Formaldehyde features a fully sealed filtration system to HEPA H13 grade, ensuring purified air is projected back into the room. By scaling up all three filtration layers, and improving filter life, Dyson engineers have taken filtration performance to the next level:

The HEPA H13-grade particle filter is made of 21 meters of borosilicate microfibres pleated 459 times (making it 3.8x larger than predecessors and the equivalent area of 2 king-size beds or 127 pieces of A4 paper) to capture 99.95 percent of pollutants, including dust and allergens as small as 0.1 microns. The larger filter lasts up to five years and can be replaced separately with the carbon filter, reducing unnecessary waste.

The new K-Carbon filter combats gases, and NO2 specifically, which can be emitted from activities like cooking or entering the home from outdoor sources, like nearby road traffic. The K-Carbon filter traps three times more NO2 than previous filters as the potassium carbonate binds onto NO2 particles forming a strong, chemical bond and ultimately increasing the capture efficacy.

The Dyson Selective Catalytic Oxidation (SCO) filter has a unique coating, with the same structure as the Cryptomelane mineral. Its billions of atom-sized tunnels break down formaldehyde molecules into tiny amounts of water and CO2. It then re-generates with oxygen from the air to keep destroying formaldehyde continuously, without needing replacement.

Our in-house team of acousticians and noise and vibration engineers re-engineered the motor bucket to achieve a low-pressure, high velocity system for the Dyson Purifier Big+Quiet Formaldehyde to project maximum airflow with minimum noise.

Broadband Helmholtz silencer is a cavity shaped to capture sound waves of certain target frequencies, formed of microporous material. As sound waves are transmitted from the source (the compressor) along the airflow pathways, the Helmholtz silencer traps sound energy and dissipates low-frequency noise.

A unique labyrinth seal controls air recirculation by extending the airflow pathway, reducing the amount of energy it holds and reducing swirl in the recirculating air. After relentless iteration, Dyson engineers found that reintroducing the air into the main flow at a 30o angle generates the least noise.

By soft mounting the motor within the compressor, we were able to isolate motor vibrations from the machine at the source before they became amplified, minimising the acoustic level generated from vibrations. This is an improvement on previous generations where the motor was hard-mounted into the compressor and then soft-mounted into the product.

The Dyson Purifier Big+Quiet Formaldehyde comes with a suite of integrated sensors. A unique Dyson algorithm cross-checks data every second, analysing the air and automatically reacting to environmental changes to purify and display live results on the LCD screen and in the MyDyson app. The MyDyson app also acts as a remote control, even when you’re not at home, or can be used to schedule and monitor purification.

Dyson Purifier Big+Quiet Formaldehyde incorporates a new CO2 sensor, in addition to the existing sensors detecting PM2.5 and PM10 pollutants, NO2, VOCs, temperature and humidity. Higher CO2 levels indoors can impact our wellbeing but can also affect our cognitive abilities. The CO2 sensor accurately reports when CO2 levels exceed recommended levels, helping to prevent you from breathing in stale air.

The industry standard test for purifiers, Clean Air Delivery Rate (CADR), has been in use since the 1980s. Purification technology has changed dramatically since then. Despite being conducted in a small test chamber of 12m with just one sensor and artificial air mixing, it is still widely used to predict purifiers' performance in real homes. However, when developing our largest, quietest, and most powerful purifier to date, Dyson engineers refused to rely solely on computational software, the CADR test, or even our existing 'Point Loading Auto Response' (POLAR) chamber.

Dyson engineers constructed an even larger, 100m test chamber in Dyson’s Hullavington campus. The chamber is equipped with 36 sensors to provide precise readings of the purifier's ability to purify the air in the equivalent to a large, open-plan living space.

The ability of purifying a large room up to 100m (10m*10m) proven from a Computational Fluid Dynamics (CFD) modelling, with the purifier placed in a corner of the room running at the maximum flow and horizontal projection reaching 10 meters to fully mix the room. The projection distance was measured from internal flow reach testing under the maximum directional airflow. The actual performance in real life condition may vary.